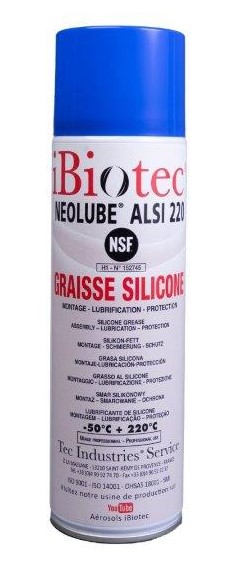

100% SILICONE GREASE

food grade contact NSF H1

approved for contact with drinking water

Specially designed for valves

joints, elastomers, rubbers

very low temperatures

Antiscaling

Dielectric insulation

Meets the specifications NATO S 736 - MIL.S.8660 B

DESCRIPTION

Colourless, odourless, non-staining lubricant that is totally harmless and sensorially inert.

Completely insoluble in water, hot water, steam, marine environments.

Resistant to the spray or pressurised distribution of water or steam.

Inert in the presence of dilute chemical products: acids, bases, mineral or vegetable oils, ethanol, glycerol.

Excellent thermal stability at high and low temperature.

Perfect dielectric resistance. Isolating grease.

Completely compatible with elastomers, thermoplastic elastomers (TPEs), high-performance plastics, bi-material seals.

Prolongs the lifespan of seals, resolves alignment fault issues and leaks.

Continuous lubrication

-50°C +220°C

|

APPROVAL CERTIFICATION N°18 CLP NY 013 |

|

|

AREAS OF USE Diving equipment, 1st level lubrication, beacons, watertight tanks, combination zip locks. Lubrication of taps and ground glass joints in laboratories. |

|

TYPICAL PHYSICO-CHEMICAL PROPERTIES

|

PHYSICAL PROPERTIES OF THE GREASE |

|||

|

PROPERTIES |

STANDARD OR METHOD |

VALUE |

UNIT |

|

Appearance |

visual |

smooth, adhesive |

nm |

|

Colour |

visual |

translucent |

nm |

|

Apparent density at 25°C (pycnometer) |

NF T 30 020 |

960 |

Kg/m³ |

|

NLGI Class |

NLGI National Lubricating Grease Institute |

3 |

Classification |

|

Thickener |

- |

Inorganic |

- |

|

Solid lubricant content |

- |

Without |

% |

|

Penetrability at 25°C Non-worked Worked, 60 strokes Worked, 1,000 strokes Worked, 10,000 strokes Worked, 100,000 strokes |

NF ISO 2137 / ASTM 2176

|

250-280 265-295 305-335 335-365 In progress |

1/10° mm 1/10° mm 1/10° mm 1/10° mm 1/10° mm |

|

Dropping point Dropping point if greater than 360°C |

NF ISO 2176 / ASTM D 566 ASTM D 2265 |

Without Infusible |

°C

|

|

Impurities > 25µm > 75µm > 125µm |

FMTS 791 3005 |

0 0 0 |

nb/ml nb/ml nb/ml |

|

PHYSICO-CHEMICAL PROPERTIES OF THE BASE OIL |

|||

|

PROPERTIES |

STANDARD OR METHOD |

VALUE |

UNIT |

|

Characteristics of the base oil |

- |

Silicone |

- |

|

Kinematic viscosity at 40°C Kinematic viscosity at 100°C |

NF EN ISO 3104 |

1000 750 |

mm2/s mm2/s |

|

Acid value (AV) |

NF ISO 6618 |

0.0 |

mg KOH/l |

|

PERFORMANCE PROPERTIES |

|||

|

PROPERTIES |

STANDARD OR METHOD |

VALUE |

UNIT |

|

Oil separation, 7 days at 40°C (bleeding) |

NF T 60 191 |

0.0 |

% of mass |

|

Oil separation 24 hours at 41kPa (bleeding under pressure) |

ASTM D 1742 |

0 |

% of mass |

|

Exudation maxi 24h at 150°C |

NATO S 736 - MIL S.8660 B | 0,1 | % |

|

Sulphated ashes |

NF T 60 144 |

0 |

% of mass |

|

Copper strip corrosion |

ASTM D 4048 |

1b |

Sizing |

|

Hoffman oxidation |

ASTM D 942 |

50 |

psi |

|

Loss by evaporation 22 hours at 121°C |

ASTM D 972 |

0.5 |

% of mass |

|

Noack evaporation loss |

NF T 60 101 CEC L-40 A-93 ASTM D5800 |

0.8 |

% of mass |

|

Elastomer swelling 70h at 212°F |

ASTM D 4289.83 |

< 0.5 |

Dimensional variation % |

|

Temporature range Continuous Peak |

- - |

-50 +220 -50 +220 |

°C °C |

|

Rotation factor |

n.dm |

50,000 |

mm.min-1 |

|

4-ball test Wear scar diameter Wear load index |

ASTM D 2266 / ISO 20 623 |

Non applicable Non applicable |

mm daN |

|

TIMKEN Test |

ASTM D 2509 |

Non applicable |

Ibs |

|

EMCOR rust-prevention test Dynamic Static |

NF T 60 135 ISO DP 6294/ ASTM D 1743 |

2 2 |

Rating Rating |

|

Resistance to water washout at 80°C |

ASTM 1264 |

< 4 |

% of mass |

* not measured or not measurable

|

ADDITIONAL PROPERTIES |

|||

|

PROPERTIES |

STANDARD OR METHOD |

VALUE |

UNIT |

|

Cold starting torque (-40°C) |

ASTM D 1478-63 |

12 |

Newton meter |

|

Operating torque (-40°C) |

- |

2 |

Newton meter |

|

Dielectric rigidity at 25°C 100Hz (disruptive field) |

IEC 156 |

2.8 |

KV cm-1 |

|

Volume resistivity at 25°C |

IEC 156 |

1.1015 |

W/cm |

|

Breakdown voltage |

IEC 156 |

16,000 |

V |

|

10 Hz dielectric constant |

NFC 26230 | 2,5 | - |

|

Loss tangent at 10 Hz |

NFC 26215 | 103 | - |

|

Volume resistivity |

- | 1015 | ohm/cm |

* not measured or not measurable

INSTRUCTIONS FOR USE

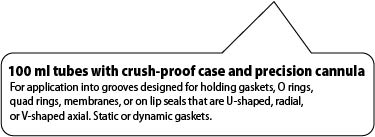

NEOLUBE® ALSI 220 is supplied in a tube, with a precision application cannula, in order to fill recesses intended to accommodate watertight seals.

Use sparingly on clean surfaces.

PRESENTATIONS

|

|

Aerosol 650 ml |

100 ml tube

|

Tin 1 L

|

Product suitable for the agro-foods industries (IAA)

Consistent with an HACCP approach or method

Risk analysis, critical factors in risk management

ISO 22 000 CODEX ALIMENTARIUS

NSF category:

H1 lubricant : can be used in areas in which food is manufactured. Can be used as a lubricant, anti-corrosion agent, as a non-stick agent for tank door hinges, as a lubricating grease for equipment in areas with potential contact with foodstuffs.

Looking for another product?

|

Discover our entire IAA range by clicking on the photo |

Manufacturing, lubrification, cleansing, protection,

IBiotec® Tec Industries® Service

offers a wide range of products reserved for industrial area

If you wish for :

a free sample

a technical advice

a product data sheet

a safety data sheet

IBiotec® Tec Industries®Service

manufacturer of technical chemical products.

Welcome to our website.

.jpg)